Neuguard's PUWER Services

We provide a wide range of professional services both standardised and taylored to meet your needs.

Provision & Use of Work Equipment (PUWER) Regulations 1998

PUWER — What the Law Requires

PUWER is legal, mandatory and enforceable in the UK. If you use work equipment or machinery, you must ensure it is:

Suitable and safe for use

Properly maintained and inspected

Used only by trained, competent personnel

Provided with appropriate guarding, controls and instructions

Failure to comply risks:

HSE enforcement & prosecution

Serious injury & downtime

Incalculable financial and reputational damage

If machinery is in your workplace, PUWER applies to you.

What Employers Must Do

To comply with PUWER, organisations must:

Assess machinery risks

Ensure equipment suitability

Implement guarding & safety measures where applicable

Maintain and inspect equipment

Train operators and maintenance staff

Keep compliance records

Straightforward in theory — difficult in reality.

This is exactly where Neuguard helps clients to achieve compliance and peace of mind.

Why Neuguard?

Neuguard provides competent, specialist PUWER support to help you:

Achieve legal compliance

Reduce risk and liability

Protect your workforce

Avoid costly enforcement action

Clear reports. Practical actions. Real-world guidance.

No unnecessary complexity. No inflated consultancy costs.

Ready to Comply with Confidence?

We help manufacturers, OEMs and industrial sites stay safe and compliant. Speak to a PUWER expert.

Book a free consultation today.

Ensure Safety

Ensure Compliance

Reduce Downtime

Reduce Costs

How do we work?

We will come to your site and perform physical assessments of the equipment under the applicable PUWER Regulations.

Neuguard have the capability of performing assessments on multiple assets from simple hand tools in a workshop to full assembly lines.

After the assessment has been completed, a report will be issued detailing all hazards/non-compliances with clearly described and illustrated remedial action recommendations to bring the equipment back into compliance.

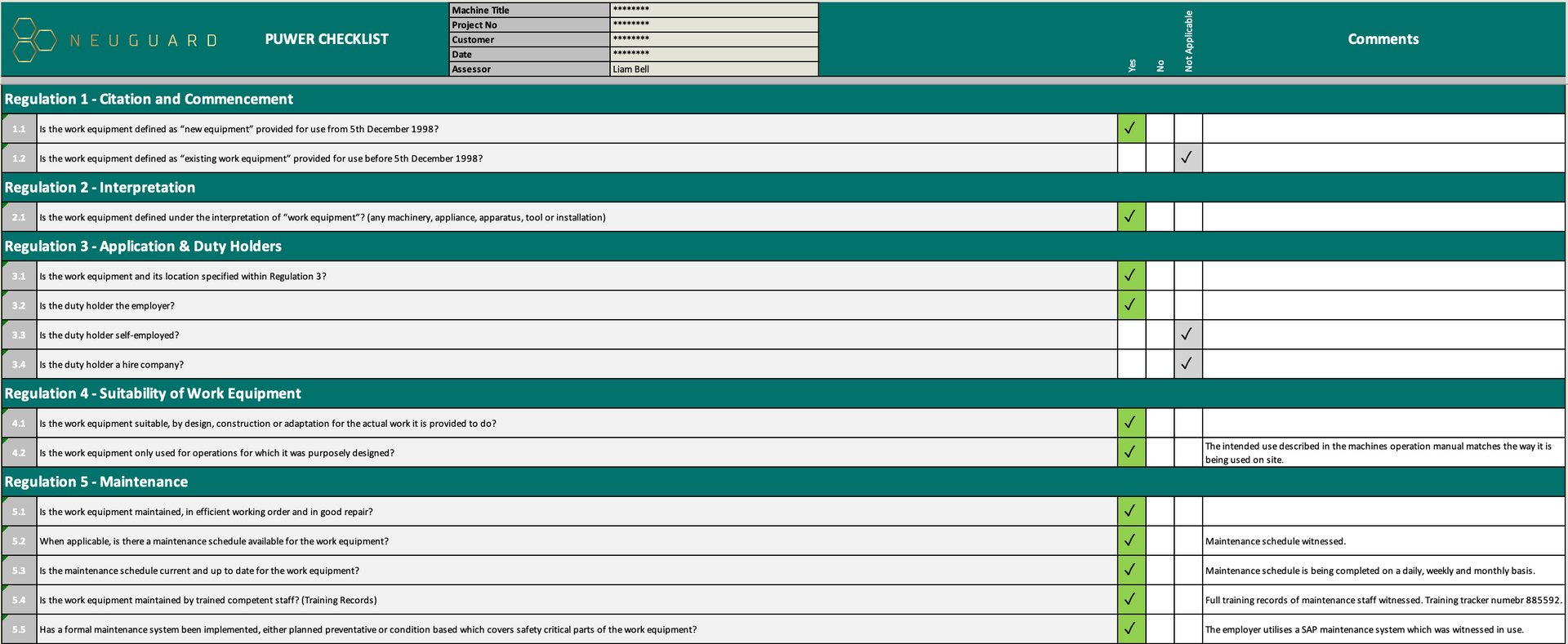

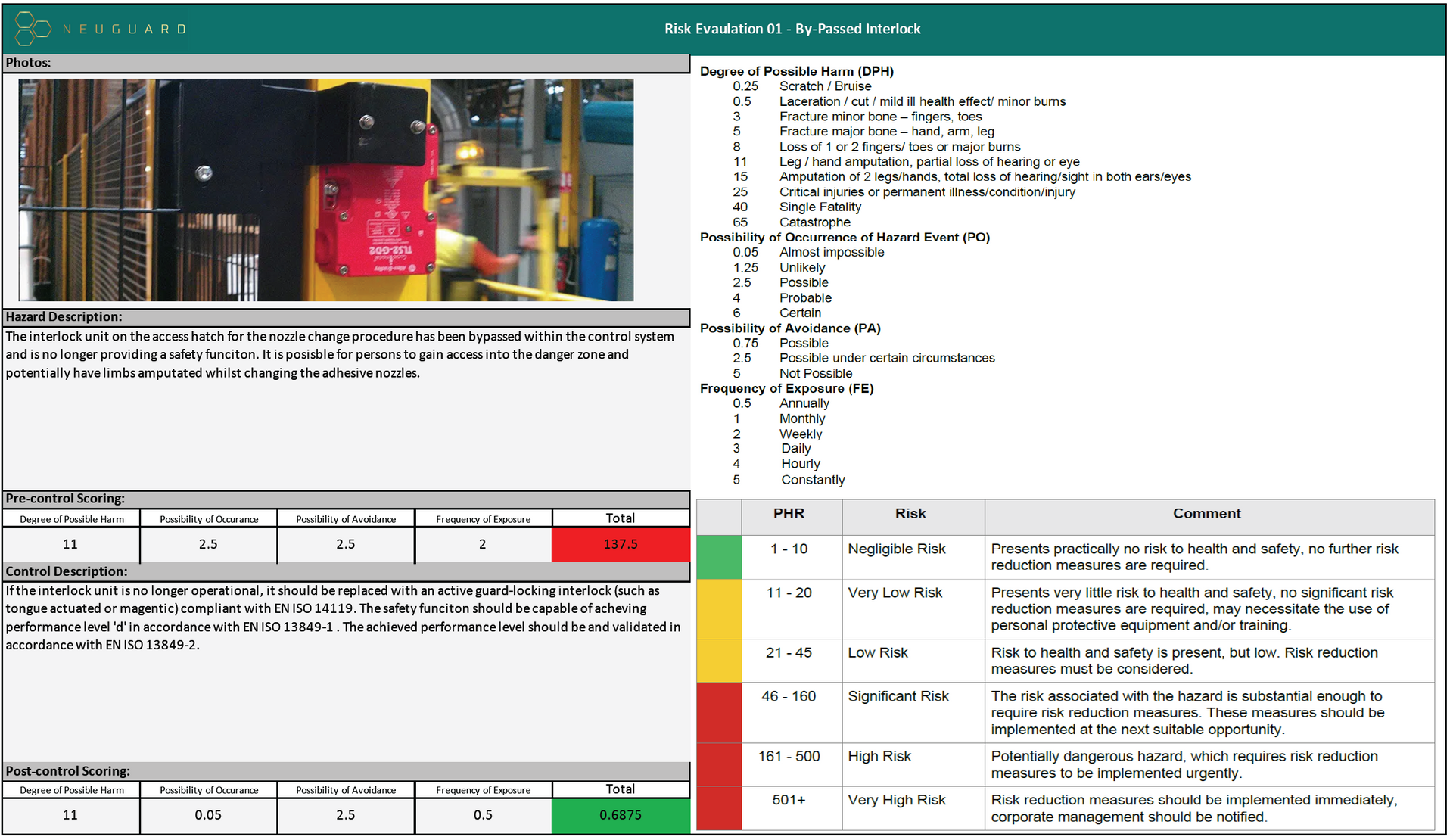

First a checklist will be filled out identifying where the equipment either complies, does not comply or is not applicable to the regulations. Then, for each non-compliance, a risk evaluation will be performed detailing the hazard identified, the risk scores associated with the hazard and recommendations for corrective action (an example of a Neuguard checklist and risk evaluation are shown).

Neuguard offers an optional service for sign-off following the completion of the corrective actions. This may be performed in person or remotely.ft